Designing a new kitchen is both enjoyable and hard work.

Which colours and materials should be used? Would a cooktop extractor with an exhaust air or recirculation system be better? All BORA cooktop extractor systems are available in both recirculation and exhaust air versions. Each system has its advantages. The best choice for each kitchen depends not least on the structural conditions. In our guide, we explain how they work and help you to make the best choice for your needs.

Our cooktop extractor systems come as either an exhaust air or recirculation model. Both systems effectively remove steam, odours and grease particles. The main difference is in the airflow: with the recirculation version, the extracted air is cleaned by a high-quality activated charcoal filter and channelled back into the room. With the exhaust air version, the air is channelled to the outside via a duct system. These basic functions apply to both BORA cooktop extractors and conventional extractor hoods.

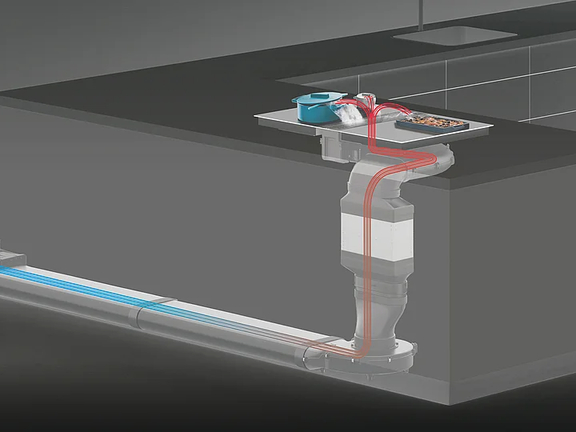

An exhaust air extractor channels the air that it draws in out into the open air. The system is linked to an exhaust pipe system with a wall sleeve, which leads to the outside via an opening in the building envelope. This opening can be in the exterior wall, the roof or the cellar.

The steam is directly suctioned away from the cookware, cleaned by a stainless steel grease filter and then channelled to the outside through a duct system. The tailored BORA Ecotube exhaust air duct system provides plenty of design freedom, enables the air to be channelled in different directions and can be assembled over long distances.

The cooking vapours, also known as waste steam, are channelled to the outside through the wall sleeve. Non-return valves in the exhaust air duct prevent outdoor air from flowing back into the building. Depending on where the system is installed, special exhaust air accessories such as exterior wall fans and tiled or flat roof fans are used.

Exhaust air systems are more difficult to install than recirculation systems and are preferably used in new builds. They remove all vapours and odours from the cooking area. Thanks to intelligent flow technology, less warm inside air is expelled from the home than by classic exhaust air or recirculation extractor hoods fitted over the hob.

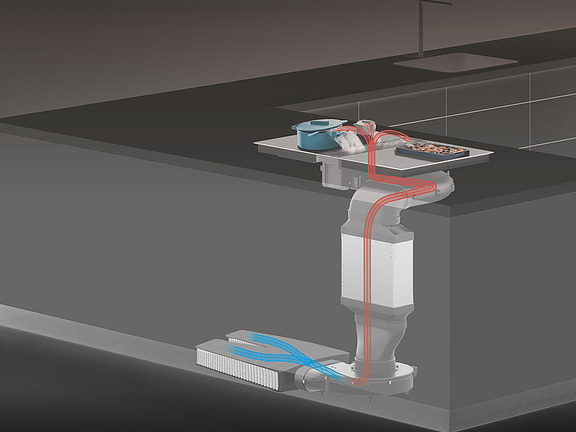

With recirculation extractor systems, the air stays in the living space. The extractor draws away the air contaminated with cooking and frying odours as well as grease molecules, effectively filters it through a grease and activated charcoal filter, and releases the purified air back into the kitchen environment. The BORA activated charcoal filter binds the odour molecules from the waste steam. These filters must be changed regularly – every one or two years – to guarantee effective extractor performance. The system will tell you when you need to change the filter and you can also consult the operating instructions.

Recirculation systems are easier to install than exhaust air systems and are frequently used in smaller apartments, rental properties and passive houses as well as low and nearly zero-energy buildings.

If you use the automatic after-run function, the cooktop extractor fan will continue to run for about 20 minutes after you have finished cooking. This thoroughly dries out the activated charcoal and binds the odour molecules more effectively. If BORA cooktop extractors with a recirculation system are properly installed in a normal indoor climate, there is no risk of condensation or mould growth.

In our video, you can see the BORA exhaust air system ducting, using the BORA Classic 2.0 as an example

Modular and compact systems – an overview of all BORA cooktop extractor systems

| System | Advantage | Disadvantage |

|---|---|---|

| Recirculation |

|

|

| Exhaust air |

|

|

What’s best: an exhaust air or recirculation extractor?

Both systems have their advantages. Exhaust air systems fully remove moisture and odours, but are more difficult to install. Recirculation systems are easier to install and ideal for passive houses and low-energy buildings; however, they require the activated charcoal filter to be changed regularly.

Discover the new generation of BORA activated charcoal odour filters. Now even more powerful.

Exhaust air or recirculation – which extractor is more suitable? There are considerable differences between both operating modes, starting with the airflow – how and where the air from the cooktop is drawn away and channelled to – and ending with maintenance. The following aspects help to decide whether a BORA recirculation or exhaust air system is more suitable.

In winter, precious energy is lost with an exhaust air extractor, as heated air is expelled to the outside together with the cooking vapours. In passive houses or particularly well insulated low-energy buildings, this can negatively affect the energy footprint. Therefore, building experts recommend opting for recirculation rather than exhaust air systems for extractors in highly insulated new builds. In many new builds, exhaust air extractors are even prohibited.

Although in comparison to conventional extractor hoods, BORA systems work with a lower flow volume and less warm inside air is expelled to the outside, in air-tight buildings recirculation is often the best option. This is because most of these buildings are fitted with controlled ventilation systems which ensure that moisture is safely removed and, together with a recirculation extractor, keep the air in the kitchen fresh. In old buildings, on the other hand, exhaust air is usually recommended as there are often significant temperature differences in these buildings, which favour the formation of condensation. With an exhaust air system, the moisture in the air is quickly expelled outside.

To effectively remove odours, when using a recirculation system, a special odour filter – an activated charcoal filter – is required as well as a grease filter. As usage increases, the surface of the activated charcoal filter is no longer able to absorb and bind the same quantity of odour molecules. Therefore, the recirculation filter needs to be changed regularly as it enables the extractor to continue to provide fresh air. The service life and operating times are specified in the cooktop extractor system operating instructions.

BORA exhaust air models have a grease filter but no activated charcoal filter as the waste steam is channelled outside.

To effectively remove odours, when using a recirculation system, a special recirculation filter – an activated charcoal filter – is required as well as a grease filter.

As usage increases, the surface of the activated charcoal filter is no longer able to absorb and bind the same quantity of odour molecules. Therefore, the recirculation filter needs to be changed regularly as it enables the extractor to continue to provide fresh air. The service life and operating times are specified in the cooktop extractor system operating instructions.

BORA exhaust air models have a grease filter but no activated charcoal filter as the waste steam is channelled outside.

Extractors with a recirculation system remove residual grease and odours, but not the waste steam generated when cooking. For this reason, when operating a recirculation system, it is important that sufficient air exchange is guaranteed. This can be through an open window or a controlled ventilation system.

Cooker hoods and cooktop extractors with exhaust air systems channel the moisture generated during cooking out of the room. However, it is still important to guarantee the exchange of air from the room and fresh air.

This particularly applies if the room has a heat source such as a wood burner, a combi boiler or a coal fire. Why? The vacuum generated by the exhaust air extractor could otherwise draw hazardous flue gases into the room.

This risk is posed by particularly air-tight buildings and heat sources that are not dependent on the air in the room like heating appliances that receive the air they use for combustion via a separate supply pipe. A window contact switch averts this hazard by only allowing the extractor to be switched on when the window is open and therefore sufficient fresh air can flow into the room. This switch is linked to the extractor motor by a cable or wireless connection and acts as a controller that monitors the position of the window sash. If the window is open, the extractor can start working.

We answer the most frequently asked questions about exhaust air and recirculation systems here.

BORA offers both, whereby exhaust air systems are ideal in new builds and where humidity is high. Recirculation systems are more energy efficient and better suited to well-insulated homes.

In BORA exhaust air systems, the steam is conducted outside through a duct system. In recirculation systems, the steam is cleaned by a grease filter and an activated charcoal odour filter, and the air is returned to the room .

Exhaust air systems channel the air to the outside, whilst recirculation systems use filters to clean the air and channel it back into the room. Downdraft extractors with exhaust air systems also remove moisture, whereas recirculation systems do not.

In some new builds and passive houses, exhaust air systems may be prohibited due to the air-tight design and energy efficiency regulations.

Many extractor hoods can be changed over to a recirculation system provided that the corresponding filters can be retrofitted. Check the manufacturer’s instructions for more detailed information.

Plan the exhaust air duct to be as short as possible, ensure that you use the correct pipe diameter, which is specified for your BORA system, and that all connections are airtight. Depending on the installation situation, special exhaust air accessories such as external wall, brick or flat roof vents may be required for the initial installation.

Yes, an activated carbon odour filter is essential, as it filters odours from the air before it is returned to the room. The filter must be replaced regularly, as it becomes saturated over time and loses its effectiveness.